News & Event

Technical Articles

2025.03.06

How to Extend the Lifespan of Your Connectors: Best Practices

Connectors play a crucial role in ensuring reliable power, signal, and data transmission in various industries, from industrial automation to outdoor applications. However, factors like moisture, dust, corrosion, and mechanical wear can reduce their performance and lifespan. To maintain optimal functionality and longevity, it’s essential to follow best practices for installation, maintenance, and usage.

In this article, we’ll explore key strategies to extend the lifespan of your connectors, helping you maximize efficiency and reduce long-term replacement costs.

1. Choose the Right Connector for Your Application

Selecting a connector that matches the environmental conditions and usage requirements is the first step in ensuring longevity. Consider the following factors:

✔ Waterproofing & Dustproofing:

Use IP68 or IP67-rated waterproof connectors (such as WEIPU sp series or sa series) for outdoor, marine, and industrial environments.

✔ Temperature Resistance:

In extreme conditions, use connectors designed for high or low temperatures.

✔ Corrosion Resistance:

For harsh environments, choose stainless steel or nickel-plated connectors (such as WEIPU cable glands or st12 series) that resist oxidation and corrosion.

✔ Mechanical Strength:

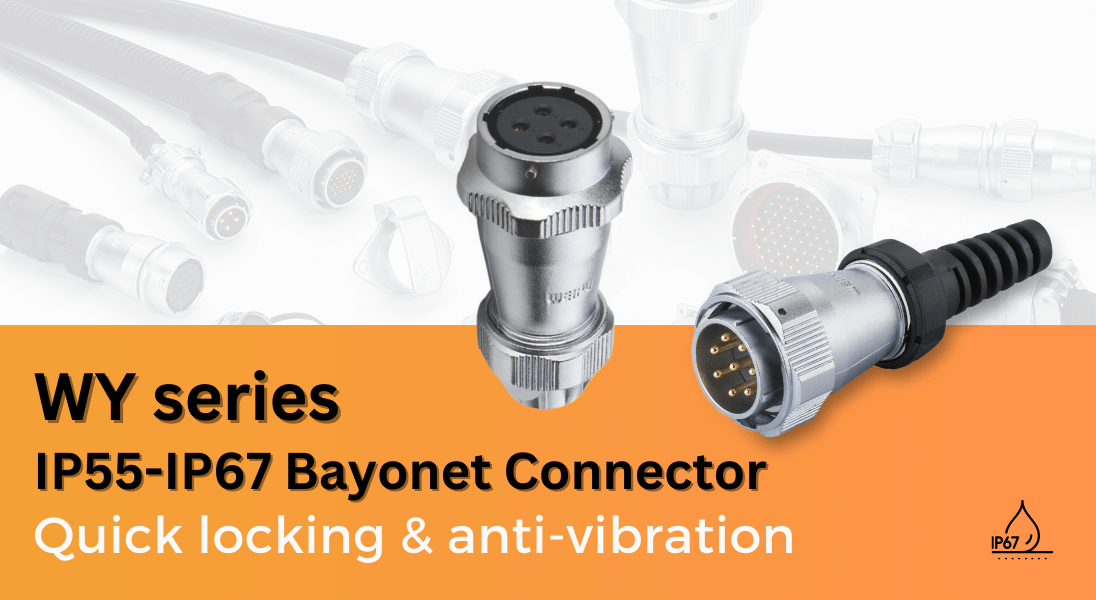

In high-vibration applications like automotive or industrial machinery, opt for anti-vibration connectors such as WEIPU wy series with bayonet coupling.

✅ Pro Tip: If your application requires long-term durability, ensure the connector’s material, sealing, and contact design align with your operating environment.

2. Proper Installation to Prevent Damage

Incorrect installation can lead to early failures, poor connections, and increased wear. Here’s how to ensure a proper setup:

✔ Follow Manufacturer Guidelines:

Use the correct tightening torque and coupling method (push-pull, thread, or bayonet coupling).

✔ Avoid Over-Tightening:

Over-tightening can damage connector threads, leading to poor mating or sealing issues.

✔ Secure Cables Properly:

Prevent cable strain by using strain relief mechanisms like WEIPU cable glands, ensuring secure connections and reducing mechanical stress.

✔ Correct Pin Alignment:

Always align the pins properly to avoid bending or breaking contact points.

✅ Pro Tip: Use cable ties or brackets to relieve stress on the connectors and avoid unnecessary pulling or bending.

3. Regular Cleaning & Maintenance

Dirt, debris, and oxidation can compromise the electrical connection over time. Regular maintenance ensures optimal conductivity and longevity:

✔ Inspect for Corrosion or Debris:

Check for oxidation, dirt buildup, or signs of wear on both the contacts and housing.

✔ Use Proper Cleaning Methods:

- For metal contacts, use contact cleaner spray to remove oxidation.

- For plastic connectors, use a soft brush and mild cleaning solution to prevent material degradation.

✔ Protect from Moisture & Contaminants:

Use sealing caps when connectors are unplugged to prevent water or dust from entering. (related article: weipu’s cap options)

✅ Pro Tip: For outdoor applications, ensure that O-rings and gaskets remain intact to maintain the waterproof seal.

4. Avoid Frequent Mating and Unmating

Repeated connection and disconnection can wear out contact points, leading to poor conductivity over time.

✔ Use Locking Mechanisms:

Bayonet or push-lock coupling connectors (such as WEIPU’s wk series) help maintain a secure connection and prevent unnecessary movement.

✔ Limit Unnecessary Plugging/Unplugging:

If connectors must be mated and unmated frequently, choose connectors rated for high mating cycles.

✅ Pro Tip: If frequent mating is unavoidable, choose connectors with gold-plated contacts, which provide better durability and conductivity.

5. Store and Handle Connectors Correctly

✔ Keep Unused Connectors in a Dry, Controlled Environment:

Store them in sealed bags or containers with moisture absorbers to prevent oxidation.

✔ Avoid Exposure to Sunlight and Extreme Temperatures:

Direct UV exposure can degrade certain plastic housings.

✔ Use Proper Protective Caps:

If connectors are not in use, apply dustproof and waterproof caps to prevent damage.

✅ Pro Tip: If storing connectors for long periods, periodically inspect them for corrosion and material degradation.

6. Choose High-Quality Connectors for Long-Term Reliability

Investing in high-quality connectors ensures better durability, lower maintenance costs, and improved system performance. WEIPU Connectors are designed for industrial, outdoor, and high-performance applications, offering:

✔ IP67 & IP68 waterproofing for dust and moisture protection.

✔ Corrosion-resistant materials such as nickel-plated brass, and high-grade plastics.

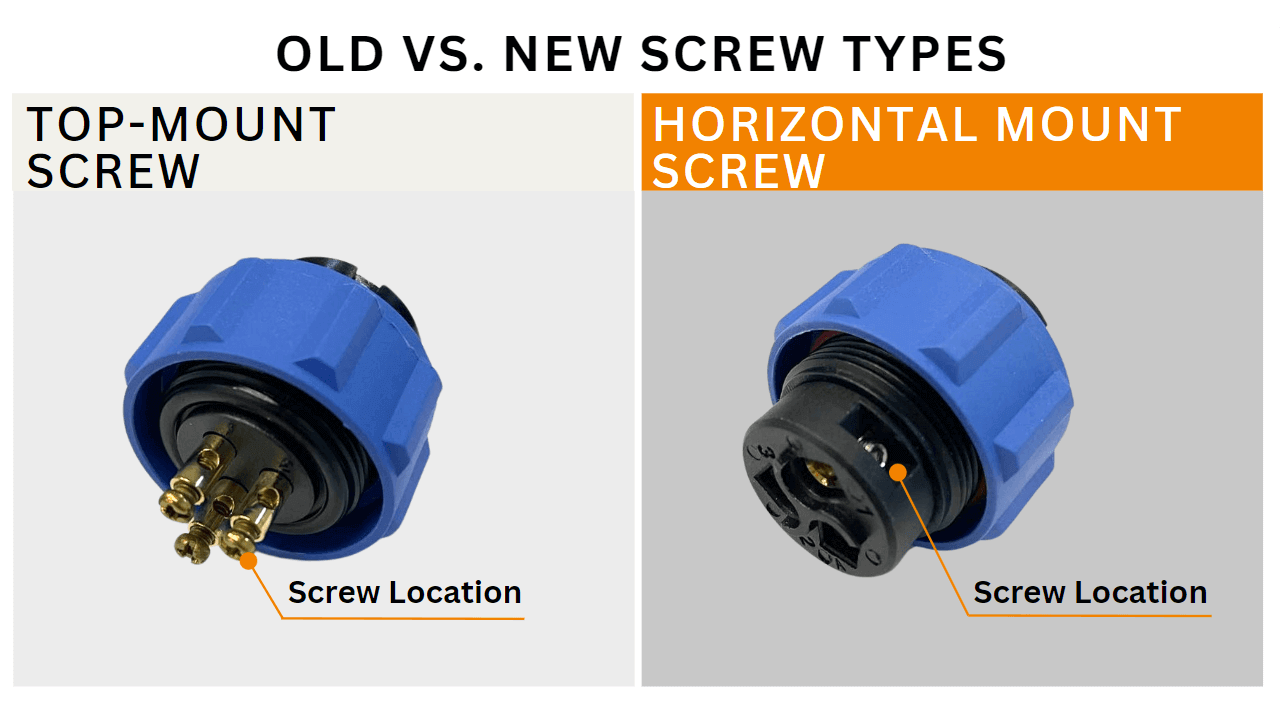

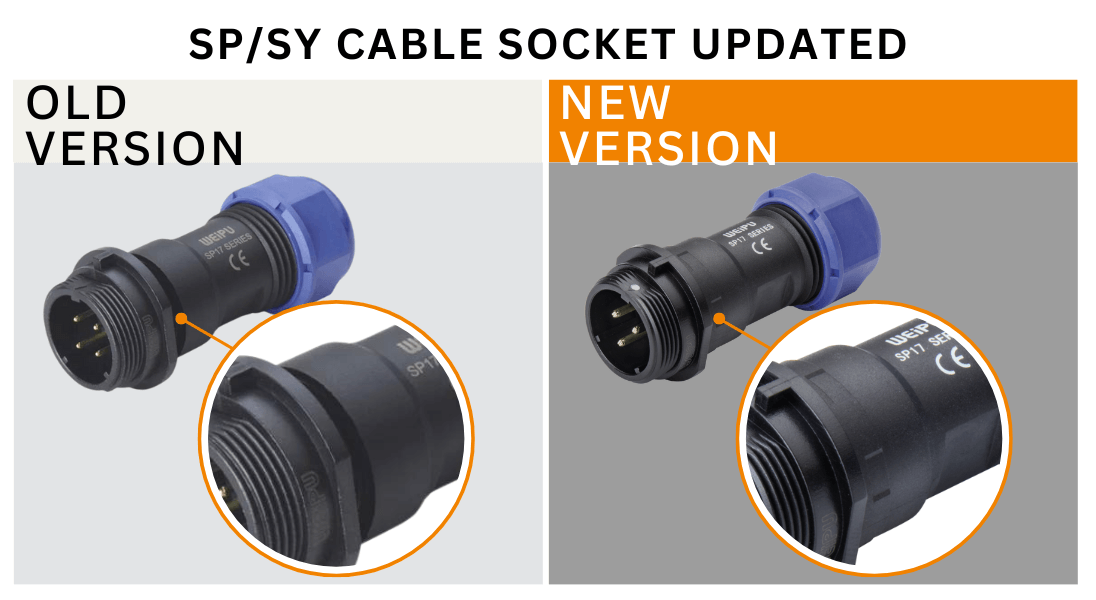

✔ Various termination options (solder, crimp, screw) for secure and stable connections.

✔ Anti-vibration locking mechanisms to withstand high-vibration environments.

Recommended WEIPU Connectors for Different Applications:

|

Application |

Recommended WEIPU Series |

|

Outdoor & Harsh Environments |

SP Series (IP68), SF/SA Series (IP67) |

|

Industrial & Automation |

WY Series (Bayonet Locking) |

|

High-Frequency Data Transmission |

SY25 Data Series (RJ45, USB, HDMI, LC) |

|

Renewable Energy (Solar, Wind) |

By choosing the right connector, following proper installation and maintenance practices, and limiting mechanical stress, you can significantly extend the lifespan of your connectors. This not only improves system reliability but also reduces replacement costs and downtime in critical applications.

Looking for durable and high-performance connectors? WEIPU offers a full range of waterproof and industrial-grade connectors designed for long-lasting, reliable connections.

Contact us today for expert guidance on selecting the right connector for your project!

Professional Waterproof Connector